Pearling

Historically, the pearling industry harvested the silver lipped pearl oyster Pinctada maxima from the wild. As far back as the 1880’s divers collected the silver lipped pearl oyster shell from the ocean floor around Broome and sold the natural pearls that were found in the oysters as well as sold the mother of pearl shell and pearl meat.

The modern day pearling industry is still reliant on the sustainable harvest of the wild giant silver lipped pearl oyster, (Pinctada maxima) but the techniques to produce top quality cultured pearls have changed and developed over time.

The sustainable harvest of wild pearl shell is managed through a quota system. Pearling companies own quota in the fishery that can be harvested by diving. The pearl shell dive fishery stretches from Exmouth Gulf through the Kimberley to the Northern Territory border and is divided into 3 zones.

The dive fishery is seasonal and occurs from April to July. Maxima’s first fishing vessel in 1987 was a traditional pearling lugger “DMcD” . In 1995 a modern 30 metre vessel “Joseph Conrad” was purchased.

During neap tides (least water movement), divers use a Hookah system of surface air supply to harvest oysters from the bottom. Divers are towed along the bottom collecting the pearl shell as they go. Dives are generally between 40 and 15 minutes depending on depth. To ensure the safety of divers decompression stops are conducted at staged intervals after each dive.

Shell collected off the bottom are placed in divers’ neck bags and then periodically emptied into a larger “Big” bag till the dive is completed. Using air filled parachutes the big-bag is floated to the surface and hauled aboard by deck crew. The pearl shell are cleaned and measured for legal size (120mm). To ensure the sustainability of the fishery smaller shell are returned to ocean beds or “patches”- areas of abundant shell numbers for future fishing.

Legal size shell are placed in 6 pocket net panels, tagged with quota tags and returned to the bottom on the company’s registered pearl shell resting site. The panels with the shell are periodically turned by divers to reduce the growth of bio-fouling and smothering by silt until they are ready for seeding.

Operating

Pearls are formed by the oysters in response to a foreign body or irritant inside the oysters shell. The oyster grows layers of shell or nacre around the foreign body as a way to protect itself. Natural pearls are the oysters response to grains of sand or other material inside the shell. Producing cultured pearls utilises this natural response to foreign bodies to produce cultured pearls.

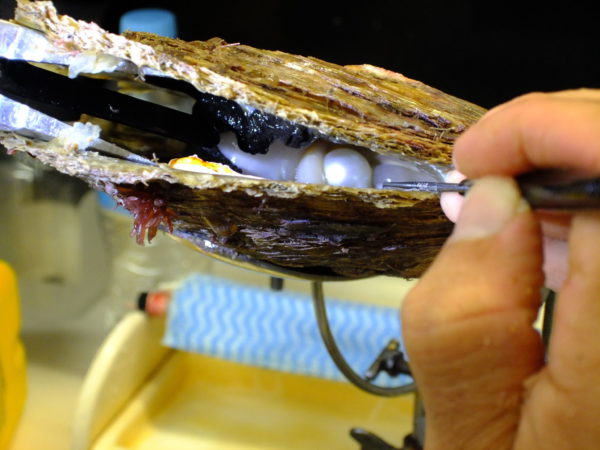

The seeding of pearl oysters is the process of placing an irritant in the oyster to produce a cultured pearl. Seeding occurs in the cooler months of June/July. Oysters are retrieved from the resting site. The Technicians uses special tools to make a small incision in the oyster. A round polished bead, from the Mississippi Freshwater muscle, is gently worked into the incision.

The seeded oysters are returned to the resting site to recover from the seeding operation and they start to lay down nacre over the bead. The divers must be very gentle when turning panels during this period. The seeded oysters are retrieved and transported in recirculated ocean water tanks to the pearl farm sites. For Maxima Pearling Company the main pearl farm site is in Cone Bay in the Buccaneer Archipelago.

Grow out

The seeded shell are kept clean of bio fouling and maintained on the farm site for a period of 2 years. They are attached to a surface long line in 6 pocket plastic mesh panels.

The panels are hung at a depth of approximately 3 metres to maximise the pearl oysters feeding on algae that is naturally occurring in the nutrient rich waters of the Kimberley.

Harvest

Harvest occurs during the cooler months when growth rates are slower and the chance of oyster stress is minimised. Only shell that produce good uniform pearl shapes with minimal blemishes are reseeded for a second or third time.

The products produced include Australian South Sea Cultured Pearls, Keshi Pearls, Mabe- Half Pearls, Pearl Meat, Hatchery Pearl Shell Spat and Mother of Pearl Shell.

Sales

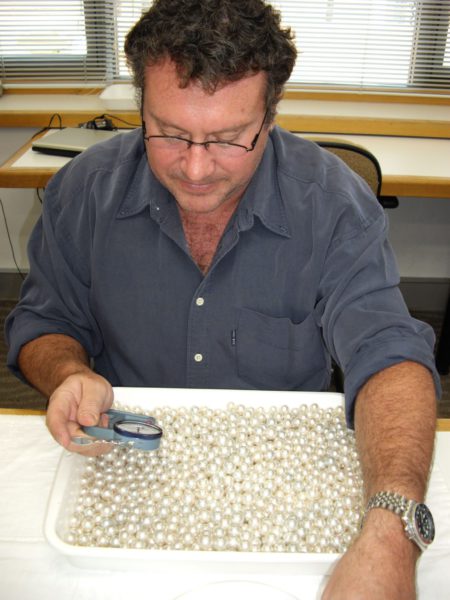

During harvest, pearls are washed to bring out their natural lustre and then graded. The internationally recognised pearl grading system is used and pearls are graded according to size, shape, color, lustre and nacre thickness.

The pearls are further cleaned and polished using specialist tumbling techniques. The pearls are graded again and expert pearl graders make up specific parcels of pearls that will attract potential buyers. A valuation based on known recent sales and specific product availability is determined as a reserve valuation before the parcels are presented at auction or private sale.

Pearls produced by Maxima can be guaranteed, when issued with a Certificate of origin signed by a Maxima Director.

Maxima offers Australian South Sea Pearls to interested buyers by appointment.

Additional pearling bi-products

Maxima has additional pearling products for sale when quantities of supply are available.

- Pearl Meat- pearl meat is sold in frozen 500 gram cryovac packs. Purchases

- Mother of Pearl Shell- shell is graded into 4 grades: A, B, C and dead. Purchases

growing promise into achievement

At the height of the Western Australian pearling boom, Maxima was the country’s third largest South Sea pearl producer.

We also have extensive experience in fish farming and still hold key marine assets that allow us to benefit from aquaculture opportunities.